Demystifying Delaminated Pickleball Paddles: Causes, Effects, and Solutions

In the world of pickleball, equipment plays a pivotal role in the quality of your gameplay. One common issue that players may encounter with their pickleball paddles is delamination. If you’ve ever wondered what a delaminated pickleball paddle is and how it can affect your performance on the court, you’re in the right place. In this blog post, we’ll unravel the mystery of delamination, explore its causes, effects, and potential solutions to help you maintain peak performance on the pickleball court.

1. What is Delamination? Delamination refers to the separation or peeling of the layers of a pickleball paddle. Most modern pickleball paddles are composed of multiple layers, often including a core material such as polymer or aluminum, sandwiched between face materials like graphite or composite. Delamination occurs when these layers detach from one another, compromising the integrity of the paddle.

2. Causes of Delamination: Delamination can result from various factors, including poor manufacturing quality, excessive heat exposure, humidity, and wear and tear from intense gameplay. Subpar adhesive materials used during paddle construction can lead to layers separating over time, while exposure to extreme temperature changes or moisture can weaken the bond between layers.

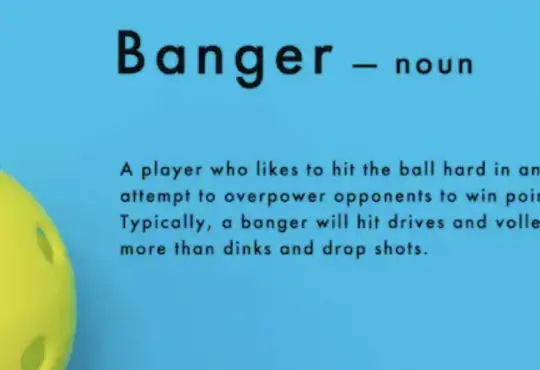

3. Effects on Performance: A delaminated pickleball paddle can significantly impact your performance on the court. The separation of layers can create dead spots on the paddle’s surface, resulting in reduced responsiveness and power during shots. Players may experience a loss of control, diminished ball spin, and an overall decline in paddle performance, ultimately affecting their ability to execute strategic plays.

4. Identifying Delamination: To determine if your pickleball paddle is delaminated, carefully inspect its surface for signs of separation or bubbling between layers. Look for irregularities or changes in texture that could indicate a compromised bond. If you notice any of these signs, it’s time to address the issue before it worsens.

5. Solutions and Prevention: If you suspect delamination, it’s essential to address the problem promptly. Contact the paddle’s manufacturer or a qualified professional to assess the damage and discuss potential solutions. In many cases, delaminated paddles cannot be fully repaired, and replacement may be necessary. To prevent delamination, store your paddle in a cool, dry place, avoid extreme temperature fluctuations, and handle it with care to minimize wear and tear.

6. Maintaining Paddle Longevity: To prolong the life of your pickleball paddle and minimize the risk of delamination, consider these maintenance tips:

- Store your paddle in a protective cover or case when not in use.

- Avoid exposing your paddle to direct sunlight or extreme temperatures.

- Regularly inspect your paddle for signs of wear, including edge damage or surface irregularities.

- Clean your paddle after each use to remove dirt and sweat buildup, which can weaken adhesive bonds.

Conclusion: A delaminated pickleball paddle is a frustrating setback that can hinder your performance on the court. By understanding the causes, effects, and preventive measures associated with delamination, you can take proactive steps to protect your equipment and ensure optimal gameplay. Remember, investing in a high-quality paddle, proper storage, and regular maintenance will not only enhance your pickleball experience but also extend the life of your paddle, allowing you to focus on mastering the game without worrying about equipment issues.